Products

99.5%-99.999% Food Grade Nitrogen Generator

PSA nitrogen production method: Based on the physical adsorption of gas molecules on the internal surface of the adsorbent, the gas separation is achieved by using the characteristic of different adsorption amounts of different gases under certain pressure of the adsorbent. Nitrogen Capacity: 1-300Nm³/hr Nitrogen Purity: 99.5-99.999% Nitrogen Pressure: 0.1-0.7Mpa (adjustable)

Send Inquiry

Product Description

The environment in which your food is manufactured in is very important for quality control. Your facility needs a clean, dry, and inert environment, which the 99.5%-99.999% food-grade nitrogen generator can provide you with. By using compressed nitrogen for the food packaging process, the risk of adding unwanted moisture to your product and manufacturing cycle is reduced. This will help keep the possibility of bacterial contamination at a minimum. 99.5%-99.999% food-grade nitrogen generator also provides your facility with a clean, sterile infrastructure which reduces the risk for cross-contamination that can affect the color, smell, or taste of your food product.

1.Parameter (Specification) of high-quality 99.5%-99.999% Food Grade Nitrogen Generator manufacturer

| Model | Nitrogen Capacity | Power | Nitrogen Purity | Feed Air Pressure | Nitrogen Pressure |

| ZR-3 | 3Nm³/hr | 0.1KW | 99.5-99.999% | 0.8-1.0Mpa | 0.1-0.7Mpa |

| ZR-5 | 5Nm³/hr | 0.1KW | 99.5-99.999% | 0.8-1.0Mpa | 0.1-0.7Mpa |

| ZR-10 | 10Nm³/hr | 0.1KW | 99.5-99.999% | 0.8-1.0Mpa | 0.1-0.7Mpa |

| ZR-15 | 15Nm³/hr | 0.1KW | 99.5-99.999% | 0.8-1.0Mpa | 0.1-0.7Mpa |

| ZR-20 | 20Nm³/hr | 0.1KW | 99.5-99.999% | 0.8-1.0Mpa | 0.1-0.7Mpa |

| ZR-30 | 30Nm³/hr | 0.1KW | 99.5-99.999% | 0.8-1.0Mpa | 0.1-0.7Mpa |

| ZR-40 | 40Nm³/hr | 0.1KW | 99.5-99.999% | 0.8-1.0Mpa | 0.1-0.7Mpa |

| ZR-50 | 50Nm³/hr | 0.1KW | 99.5-99.999% | 0.8-1.0Mpa | 0.1-0.7Mpa |

| ZR-60 | 60Nm³/hr | 0.1KW | 99.5-99.999% | 0.8-1.0Mpa | 0.1-0.7Mpa |

| ZR-80 | 80Nm³/hr | 0.1KW | 99.5-99.999% | 0.8-1.0Mpa | 0.1-0.7Mpa |

| ZR-100 | 100Nm³/hr | 0.1KW | 99.5-99.999% | 0.8-1.0Mpa | 0.1-0.7Mpa |

| ZR-120 | 120Nm³/hr | 0.1KW | 99.5-99.999% | 0.8-1.0Mpa | 0.1-0.7Mpa |

| ZR-150 | 150Nm³/hr | 0.1KW | 99.5-99.999% | 0.8-1.0Mpa | 0.1-0.7Mpa |

| ZR-200 | 200Nm³/hr | 0.1KW | 99.5-99.999% | 0.8-1.0Mpa | 0.1-0.7Mpa |

| ZR-300 | 300Nm³/hr | 0.1KW | 99.5-99.999% | 0.8-1.0Mpa | 0.1-0.7Mpa |

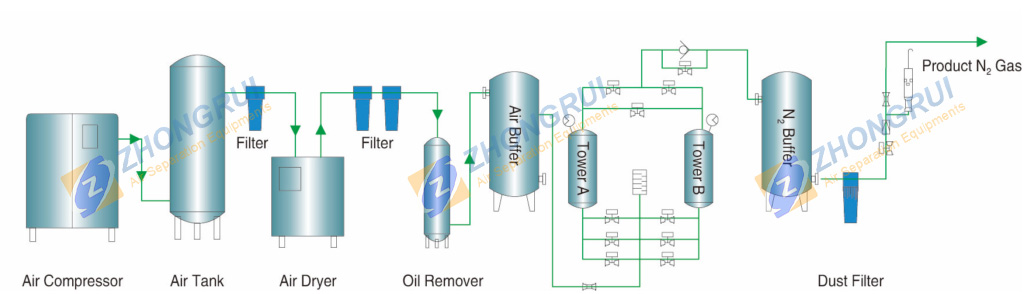

PSA (Pressure Swing Adsorption) is an advanced gas separation technology, which has an irreplaceable position in the field of current on-site gas supply. 99.5%-99.999% food grade nitrogen generator use compressed air as raw materials and carbon molecular sieves (CMS) as adsorbent to get high purity nitrogen based on the principle, which is pressure swing adsorption under normal temperature. 99.5%-99.999% food grade nitrogen generator uses two parallel adsorption towers, which are automatically running with pneumatic valves controlled by PLC, alternatively adsorb under pressure and regenerate without pressure, to separate nitrogen and oxygen, and get final required high purity nitrogen gas continuously.

2.Introduction of Advanced 99.5%-99.999% Food Grade Nitrogen Generator manufacturer

3. Features of 99.5%-99.999% Food Grade Nitrogen Generator from manufacturer

1) Easy to installation

2) Smooth operating with low noise

3) Strict quality management system

4) Superior equipment

5) Professional services

6) OEM/ODM services

7) High-quality products

8) Variety types for selection

9) Competitive price

10) Prompt delivery

4. Applications and Support of 99.5%-99.999% Food Grade Nitrogen Generator supplier

1) Beer, wine, fruit spirit, and edible oil: use N2 for holding tank, bottle blowing, and before closing, capsule to remove O2. It can prevent oxidation, spoilage, and fading of noncarbonated beverages and edible oil.

2) Puffed and fried food: N2 can prevent food fluffy and flavor reversion caused by little water in the bags. N2 also can make the shape and package beautiful, and food will not be crushed in transportation.

3) Pastry, bakery food, and vitellus pie: Flushing N2 inside the food bags can prolong freshness time and prevent food from being metamorphosed and crushed in transportation.

4) Milk Powder and soybean milk powder: just using a little N2 can prevent or reduce the agglomerate phenomenon of milk powder caused by long-time extrusion storage.

5) Cereal, nut, fruit and vegetable: Flushing N2 can prevent pests harming, and saving little O2 can reduce the breathing rate of fruit to make the fresh effect more obvious.

6) Candy and snack foods: N2 is mainly suitable used in airtight food bags.

5.Shipment of 99.5%-99.999% Food Grade Nitrogen Generator Manufacturer

Hot Tags: 99.5%-99.999% Food Grade Nitrogen Generator, Manufacturers, Suppliers, Buy, Customized, Factory, China, Made in China, Price

There are three methods of nitrogen making machine to make nitrogen.

Deep cooling nitrogen production method: Deep cooling air separation nitrogen production is a traditional nitrogen production method, which is based on air as raw material, after compression, purification, and then use heat exchange to liquefy the air into liquid air. Liquid air is mainly a mixture of liquid oxygen and liquid nitrogen, using the different boiling points of liquid oxygen and liquid nitrogen (at 1 atm, the boiling point of the former is -183℃, the latter is -196℃), through the distillation of liquid air, so that they are separated to obtain nitrogen.

Membrane separation nitrogen production: using air as raw material, under certain pressure conditions, the use of oxygen and nitrogen and other gases of different nature in the membrane with different permeation rates to make oxygen and nitrogen separation. Compared with other nitrogen equipment, it has the advantages of simpler structure, smaller volume, no switching valve, less maintenance, faster gas production (≤3 minutes), convenient capacity increase, etc. It is especially suitable for medium and small nitrogen users with nitrogen purity ≤98%, and has good function and price ratio. And when the nitrogen purity is above 98%, it is more than 15% higher in price compared with the PSA nitrogen equipment of the same specification.