News

What are the uses of Nitrogen Generator System?

2022-12-29Speaking of nitrogen, you probably don't know much about it. In fact, like oxygen, it is a gas from the earth, but the chemical reaction of the two is not the same, the laziness of nitrogen is relatively strong, at room temperature, I don't think nitrogen will react any way, and it's just this laziness, practicality in many places is also relatively strong, so what is the use of nitrogen? Here, the container nitrogen system supplier will take you to know more about it.

I. container nitrogen system suppliers take you to know the wonderful uses of nitrogen

1. Strong corrosion resistance

China Containerized nitrogen system suppliers said that in life, oxygen will cause many items to be corroded or deteriorated, and the presence of nitrogen just avoids corrosion of items, because its anti-corrosion effect is quite excellent, so in many industries, nitrogen will be used for anticorrosion, spraying it on the surface of items that need corrosion, can reduce the surface oxidation, so as to achieve the effect of fresh-keeping, so in the food industry or chemical industry The industry will always have its own figure.

2. Improve the life of items

Above, we learned that nitrogen will have a strong anticorrosive ability after all, so it can be seen that it can effectively improve the life span of items. We need to know that when some items are often in oxygen, bugs, rust, or rot will occur. Nitrogen can form a protective film on the surface, which is enough to ensure that the product does not deteriorate, so that the purpose of extending the service life can be realized. A new container nitrogen production system can bring great advantages to people's lives.

3. Nitrogenation of automobile tires

In addition to the above wonderful uses, China container nitrogen system suppliers also said that nitrogen needs to be added to automobile tires, so what is the reason? First of all, reducing tire explosion occurs. When the car is driving, there will be a lot of friction between the tire and the ground. When the weather is hot, the temperature will rise sharply, leading to an increase in tire pressure. At this time, the probability of tire explosion will increase, and nitrogen can successfully reduce the coefficient of thermal expansion.

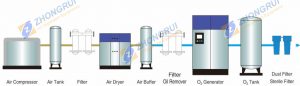

II. The working principle of the container nitrogen generation system from China manufacturer

1. Carbon molecular technology

Through carbon molecular technology, not only can self-refining be realized, but also impurities and hydrocarbons in nitrogen can be successfully removed, and nitrogen with high purity can be successfully extracted after separation. Therefore, this method is particularly widely used in many container nitrogen system suppliers, the main reason is that its purity is relatively high, can effectively guarantee the purity of nitrogen, and can also be used better when used.

2. Membrane separation technology

The main principle of this method is to distinguish the nitrogen in the air according to different characteristics, and when it is made, the air will also be compressed through the compression method of the membrane, but in the separation, there will still be some impurities and hydrocarbons. After passing the membrane separation technology, these impurities will directly adhere to the surface of the membrane and remove them all, and when the efficiency of membrane separation decreases, the purity will follow Decline.

3. Carbon boiling technology

This technology is mainly suitable for places where the air is humid or the air temperature is relatively high. According to the container nitrogen system supplier, carbon molecular technology has a good self-cleaning ability and can successfully remove water vapor from the air without being affected by the temperature, and the membrane separation technology has no self-cleaning function. A large amount of gas will directly affect the gas production efficiency of the equipment, and sometimes there will be problems with faults.

III. Problems to be paid attention to in the regular maintenance of container nitrogen production systems

1. Pay attention to safety issues

According to the container nitrogen system supplier, when maintaining the container nitrogen system, must first cut off the power supply, hang the deactivation card before the system can be overhauled, and during maintenance, we also need to pay attention to some details in the system. After all, many times, the details are not noticed, which will cause the system to fail, and in the process of use, it can also affect the manufacture of nitrogen or The purity of nitrogen.

2. Professional personnel are required

For maintenance personnel, they must have undergone professional training, and only after issuing the relevant operation certificate can they be recognized by the company, and only then can such people be qualified to overhaul and maintain the container nitrogen production system. Because such people have undergone professional training, they know a lot about some internal structures and operating specifications of oxygen concentrators, so they can also operate accurately during maintenance to avoid some bad effects.

3. Standardized operation

Generally speaking, a reliable container nitrogen production systems require regular maintenance. Regular maintenance and inspection can ensure the normal operation of the equipment and speed up the efficiency of oxygen production during use. Only if the equipment is qualified can it provide greater benefits to suppliers

All in all, Our high-efficiency container nitrogen system from suppliers have high requirements for container nitrogen production systems. Only if the system is relatively complete will the efficiency be higher and the use process will be guaranteed.