News

Oxygen making mechanism oxygen method

2023-06-25An oxygen generator is a device that extracts oxygen from the air and purifies it. It is widely used in medical, industrial and living fields to provide people with high-quality, reliable and continuous oxygen supply. This article will introduce how to make an oxygen generator.

Oxygen Mechanism Oxygen Principle

The core principle of the oxygen generator is molecular sieve adsorption technology. Under normal temperature and pressure, passing air through a molecular sieve with a special structure can absorb impurities such as nitrogen and water vapor in it, while oxygen flows out through the sieve to obtain pure oxygen. This technology is called Compression Adsorption Oxygen Technology (Pressure Swing Adsorption, PSA).

Oxygen Mechanism Oxygen Steps

1. Material selection and design

Choosing the right material and size is the first step in making an oxygen concentrator. Typically, oxygen concentrators are made of stainless steel or aluminum alloy because of their good corrosion resistance and mechanical strength. At the same time, it is also necessary to determine the size and capacity of the oxygen generator to meet the needs of different users.

2. Making Molecular Sieves

Molecular sieve is the core component of the oxygen generator, which is responsible for separating the impurities in the air. Molecular sieves are usually made of composite materials composed of various chemical elements, with certain pore structure and surface activity. When making molecular sieves, it is necessary to mix various chemical raw materials in a certain proportion, react under high temperature and high pressure, and form hard, fine and dense granular substances.

3. Making the adsorption tank

The adsorption tank is a container used to place molecular sieves, and its internal structure needs to be completely matched with molecular sieves to ensure that the gas can pass through smoothly. When making the adsorption tank, it is necessary to select the appropriate material and processing technology according to the design requirements to ensure its tightness and reliability.

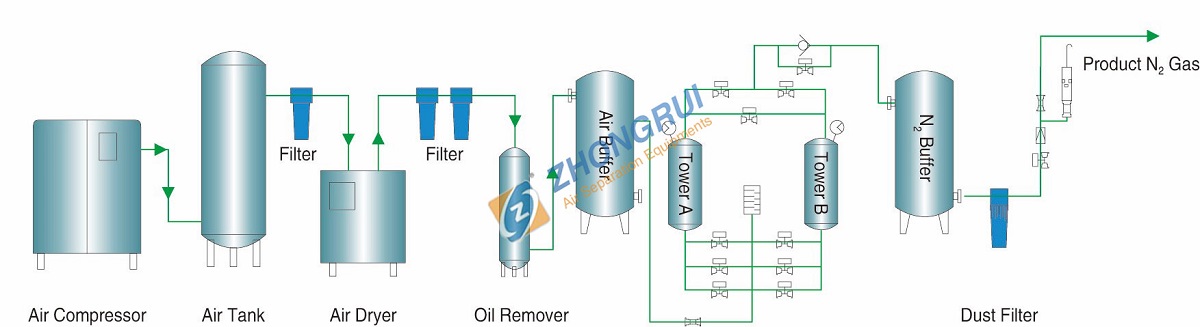

4. Assembly system

Assemble the molecular sieve and adsorption tank into the main body of the oxygen generator, and connect the oxygen outlet, air inlet, power supply and other components to form a complete system. During the installation process, it is necessary to pay attention to the connection and sealing of various components to ensure the stability and safety of the system operation.

5. Testing and Debugging

After the oxygen generator is manufactured, it needs to be tested and debugged to check whether the various indicators of the system meet the design requirements, and to find and eliminate possible faults. During the test, professional test equipment and methods are required, and the specific operation content and process depend on different oxygen generator types and specifications.

The above is the "method of making oxygen and making oxygen". The oxygen making machine is an important gas processing equipment, and its production method involves knowledge and skills in many aspects. During the production process, it is necessary to pay attention to the selection of materials, design requirements, processing technology, etc., and ensure the stable and safe operation of the system. For users, it is also very important to choose the appropriate oxygen generator brand and model to meet their own needs.