News

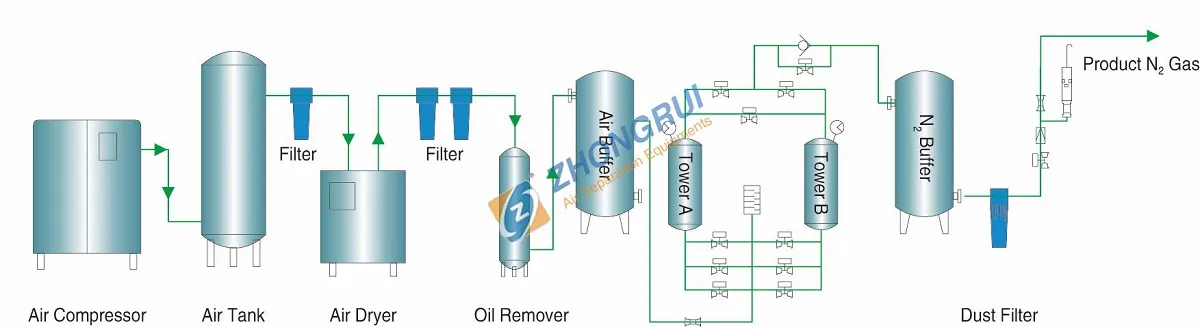

The process of making 99.6% concentration of nitrogen generator

2023-08-08A nitrogen generator is a device used to produce high-concentration nitrogen. In the fields of industry, chemistry, and medical treatment, nitrogen gas needs to be used in large quantities. However, traditional nitrogen supply methods such as cylinders or liquefied nitrogen have problems such as high cost and inconvenient storage. Therefore, the emergence of nitrogen generators greatly facilitates the use of nitrogen in these fields. application. A process for making 99.6% nitrogen gas will be introduced below.

1. Purchase materials and equipment

To make a nitrogen generator, you need to prepare some materials and equipment, including pressure gauges, molecular sieves, pipelines, solenoid valves, etc. Foremost among these are molecular sieves, a key material in the manufacture of high-purity nitrogen.

2. Make the reactor

Put the molecular sieve into a container, which is the reactor of the nitrogen generator. In the process of sieving, the integrity and dryness of the sieve should be ensured to avoid the influence of humidity or damage on the gas purity.

3. Connect the pipeline

Connect the reactor with pressure gauges, solenoid valves, etc., and a water separator needs to be installed on the pipeline to remove moisture in the air.

4. Drain and preheat

Before starting to produce nitrogen, the air in the reactor and piping needs to be evacuated. The water in the reactor is then evaporated by heating and the molecular sieves are activated.

5. Start nitrogen production

When the reactor reaches the required temperature, open the solenoid valve to start nitrogen production. By adjusting the gas pressure in the reactor, the required purity and flow rate of nitrogen can be obtained.

6. Collect Nitrogen

The produced nitrogen needs to be collected and stored. Air bags or cylinders are usually used for storage, and nitrogen can also be directly introduced into the place of use.

In general, the production of high-concentration nitrogen is more complicated, and multiple factors need to be strictly controlled to ensure the purity and quality of nitrogen. The correct operation method and equipment selection are the keys to the successful production of high-purity nitrogen.