Products

90%-95% Oxygen Generator

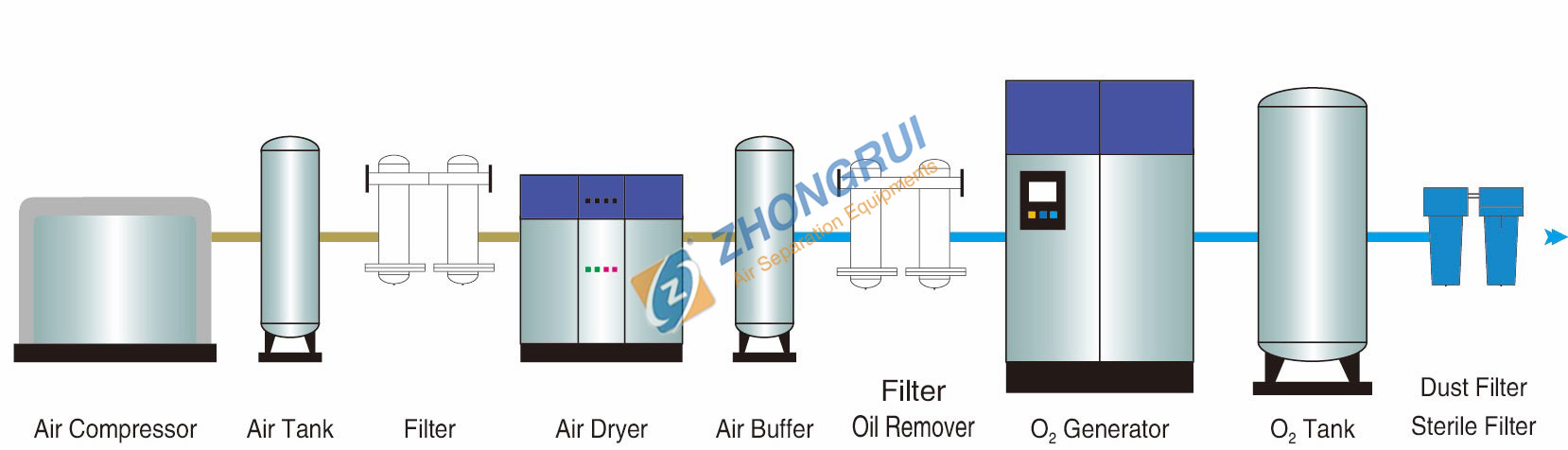

According to the principle of variable pressure adsorption, zeolite molecular sieve is used as an adsorbent, due to the selective adsorption property of zeolite molecular sieve, nitrogen in the air is adsorbed by zeolite molecular sieve in large quantities, oxygen is enriched in the gas phase, and the separation of nitrogen and oxygen is realized under the effect of variable pressure adsorption. Oxygen Capacity: 1-200Nm³/hr Oxygen Purity: 90-95% Oxygen Pressure: 0.1-0.5Mpa (150-200Bar Refilling Pressure can be offered)

Send Inquiry

Product Description

China 90%-95% Oxygen Generator Manufacturers

China 90%-95% Oxygen Generator Suppliers

China 90%-95% Oxygen Generator

90%-95% of oxygen generators from China factories have been widely used in various fields, including steel, petrochemical, medicine, electronics, textile, thermoelectricity, automobile, machinery manufacturing, aerospace, and many other fields. The company will be dedicated to general customer service, to save operating costs for users is our goal, and customer satisfaction is our purpose. We will always uphold the "quality of life, service as the cornerstone" of the enterprise spirit, and strive to jintian gas to become a compressed air purification industry leader.

1.Parameter (Specification) of 90%-95% Oxygen Generator

| Model | Capacity | Purity |

| ZRO-3 | 3Nm³/h | 90-95% |

| ZRO-5 | 5Nm³/h | 90-95% |

| ZRO-10 | 10Nm³/h | 90-95% |

| ZRO-20 | 20Nm³/h | 90-95% |

| ZRO-30 | 30Nm³/h | 90-95% |

| ZRO-50 | 50Nm³/h | 90-95% |

| ZRO-100 | 100Nm³/h | 90-95% |

| ZRO-150 | 150Nm³/h | 90-95% |

| ZRO-200 | 200Nm³/h | 90-95% |

PSA 90%-95% oxygen generator from a China factory uses clean compressed air as raw material and zeolite molecular sieve (ZMS) as adsorbent, to produce oxygen gas with Pressure Swing Adsorption (PSA) technology in average temperature. ZMS is a round granular adsorbent full of micropores inside and outside, which has characteristics of selective adsorption. N2 has a higher diffusion rate while O2 has a lower, therefore N2 is adsorbed into ZMS while O2 is out of it. By controlling the on/off state of the pneumatic valves by PLC, adsorbing under pressure, and regenerating without pressure, to separate nitrogen and oxygen gas, and create a continuous flow of oxygen with required purity.

2. Introduction of 90%-95% Oxygen Generator

3. Features of 90%-95% Oxygen Generator from manufacturer

1) Adopt a human-computer interface and intelligent control to make simple operations and supply qualified oxygen gas quickly.

2) High-efficiency filling technology of molecular sieve, to makes ZMS much tighter, firmer and longer service life.

3) Adopt international famous brands PLC and pneumatic valves, to switch automatically and make operation more stable.

4) Pressure, purity, and flowrate are stable and adjustable and can meet different requirements of customers.

5) Compact structure, nice appearance, and small occupation area.

4. Applications of 90%-95% Oxygen Generator

1) Sewage treatment: oxygen-enriched aeration for activated sludge, ponds oxygenation, and ozone sterilization.

2) Glass melting: combustion-supporting dissolution, cutting to increase yield and extend the service life of stoves.

3) Pulp bleaching and paper making: changing chlorinated bleaching to oxygen-enriched bleaching with low-cost, sewage treatment.

4) Non-ferrous metal metallurgy: oxygen-enriched smelting of steel, zinc, nickel, lead, etc. PSA technology is gradually taking the place of cryogenic technology.

5) Petrochemical and chemical industry: increasing the reaction speed and chemical production output by adopting oxygen-enriched oxidizing reaction.

6) Ore treatment: use oxygen in gold, etc. production process, to improve precious metal extraction efficiency.

7) Aquaculture: increasing dissolved oxygen in water by oxygen-enriched aeration to vastly improve fish yield, also can use oxygen when transporting lives fish.

8) Fermentation: replacing air with oxygen in fermentation to drastically improve efficiency.

9) Drinking water: providing oxygen to ozone generator from manufacturer for sterilization.

10) Medical: oxygen bar, oxygen therapy, physical health care, etc.

5.Shipment of 90%-95% Oxygen Generator manufacturer

Hot Tags:90%-95% Oxygen Generator, Manufacturers, Suppliers, Buy, Customized, Factory, China, Made in China, Price

Working principle of advanced 90%-95% Oxygen Generator:

Usually, two adsorption towers are used, one tower for adsorption and oxygen production, and one tower for desorption and regeneration. The PLC intelligent program controls the opening and closing of the pneumatic angle seat valve to make the two towers cycle alternately and produce high-quality oxygen continuously.